Introduction:

In the realm of modern telecommunications, the demand for high-speed and reliable data transmission has propelled the evolution of multi-strand optical cables. These intricate cables, composed of multiple optical fibers enclosed within protective sheaths, serve as the backbone of our digital infrastructure. From ribbon fiber to ADSS cables, each type plays a unique role in meeting diverse connectivity needs. In this article, we explore the essential considerations and best practices for producing and constructing multi-strand optical cables, delving into various types such as ribbon fiber, duct, dry fiber, dielectric, and ADSS cables.

Understanding Multi-Strand Optical Cables:

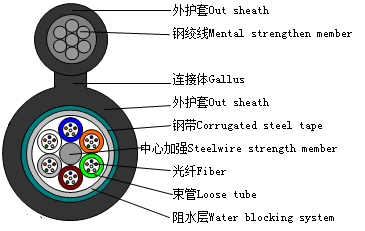

Optical fiber cables, commonly referred to as fiber optic cables, revolutionized the telecommunications industry by enabling high-speed data transmission through the use of light signals. Multi-strand optical cables consist of multiple individual optical fibers bundled together, each capable of carrying vast amounts of data over long distances. These cables are designed to be durable, flexible, and efficient, making them ideal for a wide range of applications, from telecommunications networks to data centers.

Types of Multi-Strand Optical Cables:

Ribbon Fiber Cable:

Ribbon fiber cables feature multiple optical fibers arranged in parallel rows, encapsulated within a single jacket. This design allows for high fiber density, making it suitable for applications requiring large numbers of fibers in a compact form. Precision alignment and splicing of individual fibers are essential during production to maintain signal integrity and ensure optimal performance.

Duct Cable:

Duct cables are specifically designed for installation in underground ducts or conduits, offering protection against environmental elements such as moisture, temperature fluctuations, and physical damage. Constructed with additional layers of protection, including jackets and strength members, duct cables are engineered to withstand harsh conditions and ensure reliable data transmission.

Dry Fiber Optical Cable:

Dry fiber optical cables utilize innovative dry core technology, eliminating the need for traditional gel-filled cables. This design reduces installation time and eliminates the risk of gel contamination, making it well-suited for indoor and outdoor applications where traditional cables may be impractical. The absence of gel also simplifies maintenance and repair procedures.

Dielectric Cable:

Dielectric cables are characterized by their non-metallic composition, making them ideal for environments sensitive to electromagnetic interference (EMI). By using materials with high dielectric strength to insulate and protect the optical fibers, dielectric cables ensure reliable performance in challenging conditions. Their design prioritizes signal integrity and data security, crucial aspects in modern telecommunications systems.

ADSS (All-Dielectric Self-Supporting) Cable:

ADSS cables are engineered for aerial installation without the need for additional support structures. Featuring a robust design with aramid yarns or fiberglass rods providing strength and support, ADSS cables are capable of spanning long distances across utility poles. Their self-supporting nature simplifies installation and maintenance, making them a popular choice for overhead fiber optic networks.

Key Considerations and Best Practices in Optical Cable Construction:

The production and construction of multi-strand optical cables require meticulous attention to detail and adherence to best practices to ensure optimal performance and reliability. Here are some key considerations to keep in mind:

Material Selection: Choose high-quality materials for the core, jacket, and strength members to enhance durability and longevity.

Environmental Factors: Consider the impact of temperature variations, moisture levels, UV exposure, and mechanical stress on cable performance during construction and installation.

Splicing and Termination Techniques: Employ precise splicing and termination methods to minimize signal loss and maintain reliable connections between optical fibers.

Testing and Quality Assurance: Implement rigorous testing and quality assurance protocols throughout the production process to identify and address any defects or inconsistencies that may affect cable performance.

Compliance with Standards: Adhere to industry standards and regulations governing optical cable construction and installation to ensure compatibility, safety, and reliability in network infrastructure.

Conclusion:

Multi-strand optical cables represent the lifeline of modern communication networks, enabling seamless data transmission and connectivity across vast distances. By mastering the construction and production of these cables, telecommunication providers can meet the growing demands for high-speed and reliable data transmission while ensuring the integrity and security of critical information. Through a combination of advanced technology, precise craftsmanship, and adherence to industry standards, the future of optical cable construction promises to unlock new possibilities in the realm of digital connectivity.