In the realm of telecommunications and data transmission, optical fiber cables stand as the ultimate conduit of information. Among these, the GYFH38 optical fiber cable holds a pivotal role, combining advanced production technology with versatile engineering applications. This article delves into the comprehensive technical description of the GYFH38 optical fiber cable, exploring its production, structure, performance characteristics, and diverse applications across various industries.

Production Technology

The production of GYFH38 optical fiber cables begins with meticulous planning and precision engineering. Modern manufacturing processes involve highly specialized equipment and stringent quality control measures to ensure reliability and performance. Here’s a breakdown of the key production stages:

Preform Manufacturing: The process initiates with the creation of a preform, typically made from high-purity silica. This preform serves as the foundational material for the optical fiber. Silica rods are precisely heated and fused together in a controlled environment to form a solid cylinder.

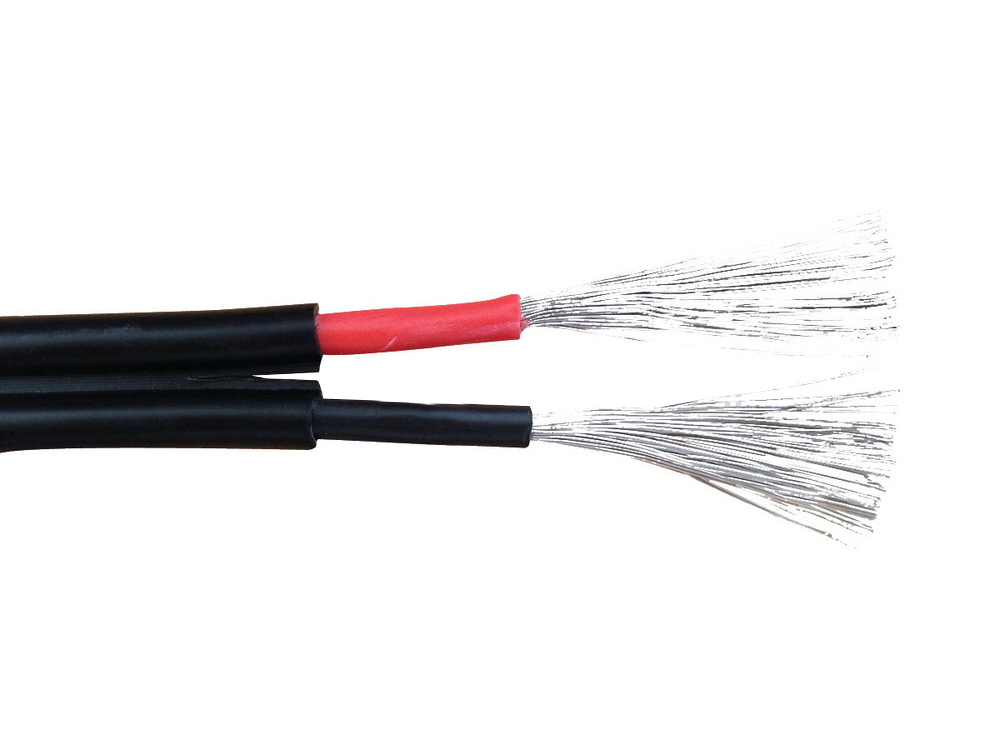

Drawing and Coating: The preform undergoes a drawing process where it is heated and stretched to reduce its diameter significantly while maintaining uniformity. This results in a thin, flexible glass fiber. Immediately after drawing, the fiber is coated with protective layers to enhance durability and minimize signal loss. These coatings may include acrylate or polyimide materials.

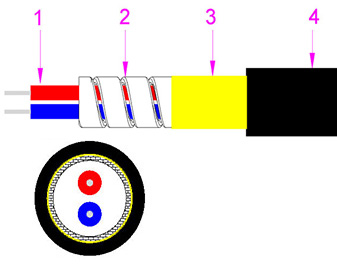

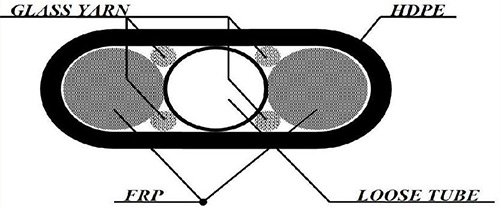

Cabling: Multiple coated fibers are then assembled into a cable structure. Depending on the design requirements of GYFH38, these fibers may be bundled together with strength members such as aramid yarns or fiberglass rods to provide mechanical support and protection against external stresses.

Jacketing: The entire cable assembly is enclosed within an outer jacket made from materials like polyethylene (PE) or polyvinyl chloride (PVC). The jacket provides additional protection against moisture, abrasion, and environmental factors.

Testing and Quality Assurance: Throughout the production process, rigorous testing is conducted to ensure adherence to industry standards. Optical fibers are tested for attenuation, dispersion, and mechanical strength, while the completed cables undergo comprehensive performance evaluations to verify reliability and signal integrity.

Engineering Specifications and Performance Characteristics

The GYFH38 optical fiber cable is engineered to meet demanding specifications, making it suitable for a wide range of applications. Key performance characteristics include:

Bandwidth and Data Transmission: GYFH38 cables offer high bandwidth capabilities, enabling the transmission of large volumes of data over long distances with minimal signal degradation. This makes them ideal for supporting high-speed internet, telecommunications networks, and data centers.

Low Attenuation: The optical fibers within GYFH38 cables exhibit low attenuation rates, ensuring that signals travel efficiently over extended distances without significant loss. This characteristic is critical for maintaining signal integrity and reliability in long-haul communication networks.

Temperature and Environmental Resistance: Designed to operate in diverse environmental conditions, GYFH38 cables are resistant to temperature fluctuations, moisture, and chemical exposure. This resilience ensures consistent performance in harsh outdoor environments and industrial settings.

Flexibility and Installation Ease: The lightweight and flexible design of GYFH38 cables facilitates easy installation and deployment across various infrastructure projects. They can be routed through ducts, aerial installations, or buried underground, accommodating different installation requirements.

Applications Across Industries

The versatility of GYFH38 optical fiber cables extends across numerous industries, playing a crucial role in modern infrastructure and technology solutions:

Telecommunications: In telecommunications networks, GYFH38 cables form the backbone for high-speed internet services, telephony systems, and cable television distribution. Their high bandwidth capabilities support the growing demand for multimedia content and data-intensive applications.

Data Centers: Within data centers, GYFH38 cables facilitate reliable and efficient data transmission between servers, storage systems, and networking equipment. Their low latency and high data transfer rates contribute to enhanced operational efficiency and responsiveness in cloud computing environments.

Industrial Automation: Industrial applications leverage GYFH38 cables for real-time data acquisition, control systems, and machine-to-machine communication. They enable seamless integration of automation technologies, enhancing productivity and process efficiency in manufacturing and logistics sectors.

Smart Cities: GYFH38 optical fiber cables underpin the infrastructure of smart cities by supporting advanced technologies such as smart grids, surveillance systems, and environmental monitoring. They enable interconnected systems to efficiently collect and analyze data for improved urban management and sustainability.

Healthcare and Education: In healthcare, GYFH38 cables facilitate telemedicine services, digital imaging, and electronic health records, enabling remote patient monitoring and diagnostic capabilities. In education, they support distance learning initiatives and online educational resources, ensuring seamless connectivity for students and educators.

Future Trends and Innovations

Looking ahead, the evolution of GYFH38 optical fiber cables continues to be driven by advancements in materials science, manufacturing techniques, and telecommunications standards. Future innovations may focus on:

Increased Transmission Speeds: Research into new fiber designs and signal processing techniques aims to achieve even higher data transfer rates, supporting emerging applications such as 5G networks and beyond.

Enhanced Environmental Sustainability: Efforts to develop eco-friendly materials and manufacturing processes will reduce the environmental footprint of optical fiber production and deployment.

Integration with IoT and AI: Optical fiber networks will play a pivotal role in supporting the proliferation of IoT devices and artificial intelligence applications, facilitating real-time data analytics and smart system interactions.

Conclusion

In conclusion, the GYFH38 optical fiber cable epitomizes the pinnacle of modern telecommunications infrastructure. From its sophisticated production technology to its diverse engineering applications across industries, GYFH38 cables exemplify reliability, performance, and versatility. As technological advancements continue to shape the landscape of global connectivity, GYFH38 remains at the forefront, enabling seamless data transmission and supporting the digital transformation of society.

This article has provided an in-depth exploration of the technical intricacies and practical applications of GYFH38 optical fiber cables, underscoring their indispensable role in the modern era of information exchange and connectivity.