Introduction

PVC insulated electrical wire is an essential component in modern electrical installations, providing safety and efficiency in various applications. This article delves into the characteristics of PVC insulated wires, their advantages, common uses, and best practices for installation and maintenance.

What is PVC Insulated Electrical Wire?

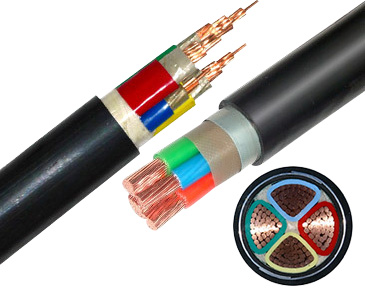

PVC insulated electrical wire consists of conductors, typically made from copper or aluminum, that are covered with a layer of polyvinyl chloride (PVC). This insulation serves multiple purposes: it protects the conductor from environmental factors, prevents electrical shocks, and reduces the risk of short circuits. PVC is chosen for its durability, flexibility, and resistance to moisture, chemicals, and abrasion.

Types of PVC Insulated Electrical Wire

There are various types of PVC insulated electrical wires, including:

-

Single-Core Wire: Made of one conductor, used for simple electrical circuits.

-

Multi-Core Wire: Contains multiple conductors, suitable for more complex applications requiring flexibility and versatility.

-

Flexible PVC Wire: Designed for applications that require bending and movement, such as in portable devices and equipment.

-

Armored PVC Wire: Features an additional layer of protection, making it suitable for outdoor and industrial use.

Applications of PVC Insulated Electrical Wire

PVC insulated electrical wires are widely used across different sectors, including:

-

Residential Wiring: Used in homes for lighting, outlets, and appliances.

-

Commercial Wiring: Essential for electrical installations in offices, retail spaces, and other commercial buildings.

-

Industrial Applications: Utilized in factories and manufacturing plants for machinery and equipment.

-

Automotive Wiring: Commonly used in vehicles for electrical systems.

-

Telecommunications: Employed in data cables and communication systems.

Benefits of PVC Insulated Electrical Wire

-

Safety: The PVC insulation provides excellent protection against electrical shocks and short circuits. It minimizes the risk of fire hazards associated with electrical faults.

-

Durability: PVC is resistant to moisture, chemicals, and UV rays, ensuring the longevity of the wire even in challenging environments.

-

Flexibility: PVC insulated wires are highly flexible, making them easy to install in various applications and configurations.

-

Cost-Effectiveness: Compared to other insulating materials, PVC is relatively inexpensive, offering a budget-friendly option without compromising quality.

-

Low Maintenance: PVC insulated wires require minimal maintenance, reducing long-term operational costs.

Best Practices for Installation

-

Choose the Right Type: Select the appropriate type of PVC insulated wire based on the specific requirements of the application. Consider factors such as voltage rating, current carrying capacity, and environmental conditions.

-

Follow Electrical Codes: Adhere to local electrical codes and standards during installation to ensure safety and compliance. This includes proper grounding and circuit protection measures.

-

Avoid Overloading: Do not exceed the rated current capacity of the wire to prevent overheating and potential hazards. Always calculate the load accurately before installation.

-

Proper Routing: When installing wires, avoid sharp bends and kinks that could damage the insulation. Use cable trays or conduits to protect the wires in exposed areas.

-

Regular Inspections: Conduct routine inspections of the electrical system to identify any signs of wear or damage. Look for frayed insulation, exposed conductors, and signs of overheating.

Maintenance and Troubleshooting

-

Keep Wires Dry: Ensure that the installation area is dry to prevent moisture buildup, which can compromise insulation integrity.

-

Protect from Pests: Rodents and insects can damage wires. Use protective conduits and ensure that installation areas are free from potential pest entry points.

-

Address Faults Promptly: If any faults are detected, such as flickering lights or tripped breakers, address them immediately to prevent further damage or hazards.

-

Use Quality Connectors: When connecting wires, use high-quality connectors to ensure a secure and reliable electrical connection. Poor connections can lead to increased resistance and heat buildup.

-

Upgrade When Necessary: If the electrical demand increases, consider upgrading to a wire with a higher current rating to accommodate the load safely.

Conclusion

PVC insulated electrical wire plays a crucial role in ensuring the safety and efficiency of electrical systems in various applications. Its durability, flexibility, and cost-effectiveness make it a preferred choice for many professionals in the industry. By understanding the benefits, applications, and best practices for installation and maintenance, users can optimize the performance of their electrical systems and ensure long-lasting safety and reliability. Properly installed and maintained PVC insulated wires can contribute significantly to the overall functionality and safety of electrical installations, making them an indispensable component in modern electrical engineering.