In the contemporary era, where connectivity and data transmission are paramount, optical fiber cables have become the backbone of modern communication networks. The advancements in optical fiber technology have revolutionized the way we transmit information, making data transfer faster, more reliable, and capable of handling vast amounts of information over long distances with minimal loss. This article delves into the innovations and technologies in optical fiber cable manufacturing that are driving these capabilities.

1. Introduction to Optical Fiber Cables

Optical fiber cables are composed of multiple strands of ultra-pure glass or plastic fibers that transmit light signals, converting them into data. These cables are known for their superior performance compared to traditional copper cables due to their high bandwidth, low loss, and resistance to electromagnetic interference. They are indispensable in telecommunications, internet services, medical equipment, and many other fields.

2. Historical Context and Evolution

The journey of optical fiber technology began in the 1960s, driven by the need for better communication methods. Early developments focused on reducing signal loss and enhancing material purity. Over the decades, significant breakthroughs have been made in materials science, manufacturing processes, and design innovations, leading to the sophisticated optical fiber cables we use today.

3. Core Components of Optical Fiber Cables

3.1. Core and Cladding

The core is the central part of the fiber, typically made of glass or plastic, where light signals travel. Surrounding the core is the cladding, which has a lower refractive index to reflect the light back into the core, ensuring signal integrity. The quality of these materials is crucial for minimizing signal loss and maintaining high transmission quality.

3.2. Coating and Sheathing

The coating and sheathing protect the delicate core and cladding from environmental damage and mechanical stress. These layers are made from various materials, including acrylate polymers and rugged plastics, depending on the application. Advances in these protective layers have significantly improved the durability and lifespan of optical fiber cables.

4. Advanced Manufacturing Processes

4.1. Preform Fabrication

The process begins with the creation of the preform, a cylindrical piece of ultra-pure glass. Techniques such as Modified Chemical Vapor Deposition (MCVD), Outside Vapor Deposition (OVD), and Vapor-phase Axial Deposition (VAD) are employed to create preforms with precise refractive index profiles. These methods ensure the highest purity and consistency, resulting in superior optical performance.

4.2. Fiber Drawing

Once the preform is ready, it is heated to around 2000 degrees Celsius and drawn into thin fibers. This drawing process is highly controlled to maintain consistent diameter and quality. Real-time monitoring systems ensure that the fibers meet stringent specifications, reducing defects and enhancing performance.

4.3. Coating Application

Immediately after drawing, the fibers are coated with a primary protective layer to prevent surface damage and preserve the fiber’s strength. Advanced coating technologies, including UV-curable coatings, provide robust protection while maintaining the flexibility needed for installation.

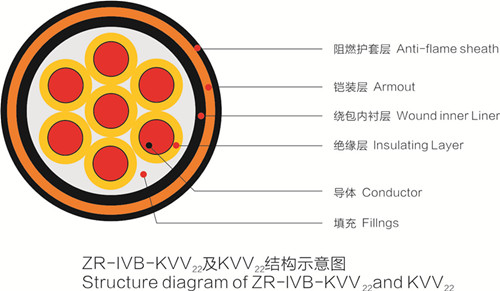

4.4. Cable Construction

The coated fibers are then assembled into cables by bundling multiple fibers together, adding additional protective layers, and incorporating strength members such as aramid yarn or steel wires. This step ensures the cable can withstand various environmental conditions, mechanical stress, and installation challenges.

5. Innovations in Optical Fiber Technology

5.1. Bend-Insensitive Fibers

One of the significant innovations in recent years is the development of bend-insensitive fibers. Traditional optical fibers suffer from signal loss when bent too tightly. Bend-insensitive fibers feature modified core and cladding structures that allow them to maintain performance even under tight bending conditions. This innovation is critical for urban installations, data centers, and other environments where space is at a premium.

5.2. High-Density Cables

As data demands grow, there is an increasing need for higher capacity cables. High-density optical fiber cables pack more fibers into a single cable without increasing its size, offering greater capacity for data transmission. This is achieved through innovations in cable design and the use of thinner, yet stronger, protective materials.

5.3. Multi-Core Fibers

Multi-core fibers incorporate multiple cores within a single cladding, allowing parallel data transmission channels within one fiber. This significantly increases the data-carrying capacity of a single fiber cable and is essential for applications requiring massive data throughput, such as data centers and high-performance computing networks.

5.4. Enhanced Attenuation Performance

Advanced manufacturing techniques and material improvements have led to fibers with lower attenuation rates, meaning less signal loss over long distances. This enhancement reduces the need for signal boosters and repeaters, lowering overall network costs and improving reliability.

5.5. Specialty Fibers

Beyond telecommunications, specialty fibers are designed for specific applications. For example, medical-grade fibers are used in endoscopy and laser surgeries, while radiation-resistant fibers are used in nuclear facilities. These fibers are engineered to meet the unique requirements of their respective fields.

6. Quality Control and Testing

Ensuring the quality and performance of optical fiber cables is paramount. Manufacturers employ rigorous testing protocols to verify the properties of the fibers, such as tensile strength, attenuation, bandwidth, and resistance to environmental factors. Advanced testing equipment and methodologies, including Optical Time-Domain Reflectometers (OTDRs) and spectral analysis, are used to detect and rectify any defects during production.

7. Environmental Considerations and Sustainability

The optical fiber industry is increasingly focusing on sustainability. Efforts include reducing the environmental impact of production processes, using eco-friendly materials, and developing recycling programs for old cables. Innovations such as low-energy manufacturing techniques and biodegradable sheathing materials are being explored to make the industry more sustainable.

8. Case Studies: Real-World Applications

8.1. Urban Connectivity

In densely populated urban areas, the demand for high-speed internet and reliable communication networks is ever-growing. Bend-insensitive fibers and high-density cables have enabled efficient deployment of fiber optic networks in cities, overcoming space constraints and providing residents with fast and reliable connectivity.

8.2. Data Centers

Data centers form the backbone of the digital economy, supporting cloud services, big data analytics, and more. Multi-core fibers and high-capacity cables are essential to meet the data transfer needs of these facilities. With innovations in fiber technology, data centers can achieve higher efficiency and handle larger volumes of data.

8.3. Medical Applications

In the medical field, specialty fibers are transforming diagnostic and surgical procedures. Medical-grade fibers used in imaging equipment and laser surgeries provide high precision and reliability, enhancing patient outcomes. The development of biocompatible and flexible fibers has opened new possibilities in minimally invasive medical procedures.

8.4. Industrial Automation

Optical fibers are also crucial in industrial automation, where they are used for sensing, monitoring, and communication in harsh environments. Radiation-resistant and temperature-tolerant fibers ensure reliable operation in challenging conditions, contributing to the efficiency and safety of industrial processes.

9. Future Trends and Developments

9.1. 5G and Beyond

The rollout of 5G networks and future generations of wireless technology will heavily rely on optical fiber infrastructure. High-capacity, low-latency fibers will be essential to support the massive data rates and connectivity demands of these advanced networks.

9.2. Quantum Communication

Quantum communication represents the next frontier in secure data transmission. Research is ongoing to develop optical fibers capable of supporting quantum key distribution, ensuring ultra-secure communication channels for sensitive data.

9.3. Integrated Photonics

Integrated photonics involves incorporating optical components directly onto microchips, enabling faster and more efficient data processing and transmission. This technology holds the potential to revolutionize data centers, telecommunications, and various other fields by significantly enhancing speed and reducing energy consumption.

9.4. Sustainable Manufacturing

Environmental sustainability will continue to drive innovation in optical fiber manufacturing. Future developments will focus on further reducing the carbon footprint of production processes, utilizing recyclable materials, and enhancing the lifecycle management of optical fiber products.

10. Conclusion

The innovations and technologies in optical fiber cable manufacturing have propelled the industry forward, enabling faster, more reliable, and higher-capacity communication networks. From bend-insensitive fibers to multi-core designs, these advancements are addressing the growing demands of modern connectivity. As we look to the future, continued innovation and a focus on sustainability will be key to meeting the challenges and opportunities in the evolving landscape of optical fiber technology.

By staying at the forefront of these technological advancements, manufacturers are not only enhancing the performance and reliability of optical fiber cables but also paving the way for a more connected and sustainable future. The journey of optical fiber technology is far from over, and the coming years promise even more exciting developments that will shape the way we communicate and interact with the world.